Our technology

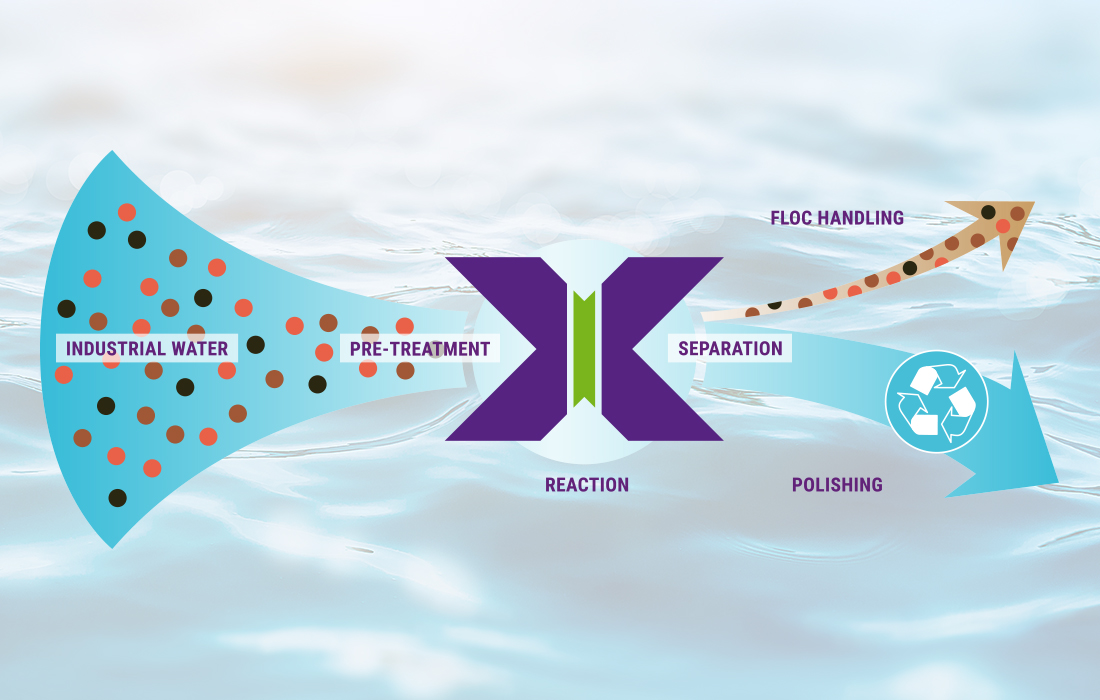

AxoPur separates dirty water into two fractions: clean water and a dry solid phase, which we call flock.

The process does not generate any difficult-to-handle sludge or concentrate stream that requires further treatment. Most toxic and problematic pollutants are removed with the technology, including microorganisms, suspended solids, transition metal ions, phosphorus, organic substances, PFAS, microplastics, pharmaceutical residues, etc. Even emulsified oils and fats are effectively removed. The process from dirty to clean water takes place in just a few minutes.

AxoPur is suitable for the treatment of:

- Industrial process and wastewater

- Various forms of leachate from landfills and storage sites

- Stormwater from industrial and other activities

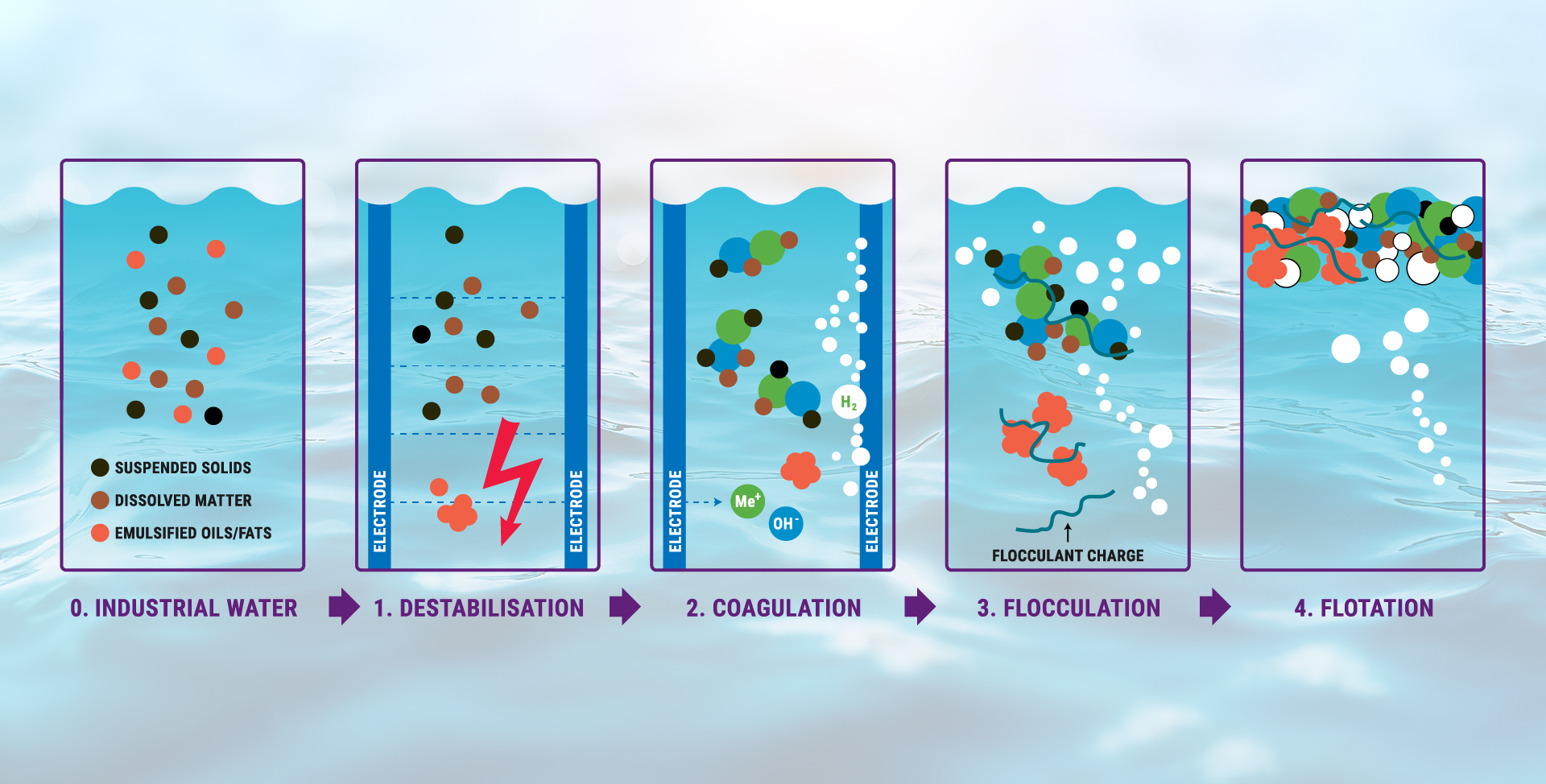

- The driving force of the AxoPur process is electricity in the form of both voltage and current. A handful of mechanisms work together to coalesce, coagulate, precipitate, and finally separate pollutants from the water.

The consumables in the process are:

- Sacrificial electrodes inside the reactor, which require regular replacement of the reactors

- (Green) electricity

- Flocculation polymer

- Acid/base for pH adjustment (depending on incoming pH)

Separation of flock

The pollutants are separated from the water, not in the form of a concentrated flow or voluminous sludge, but in the form of a minimal amount of solid flock. This flock has an extraordinary property in its ability to spontaneously self-drain and is also suitable for mechanical pressing to achieve a particularly high dry content.

Fast and efficient

Our purification process is energy efficient, fast, and environmentally friendly. It enables increased recirculation and reuse of process water, resulting in a uniquely sustainable overall solution.

For particularly demanding applications, AxoPur can be used in combination with a complementary polishing step. Axolot designs a comprehensive solution in these cases.

Product Program

We build AxoPur systems for continuous operation. The system can also be easily run intermittently. The hydraulic capacity of our systems starts at 1 m³/h. The actual capacity depends on both the flow and the amount of contaminants in the flow.

Currently, the largest system we have designed is 300 m³/h, but there is no technical upper limit. Small systems, roughly up to 30 m³/h, are standardized and can be provided built inside a container. Larger systems are customized for each individual case. Container-based solutions require access to a level and hardened surface, fresh water for flushing, and 400V 32-64A power supply.

The system design is modular in its approach, which makes it easy to expand a plant as the needs grow.

An AxoPur system includes a rectifier, one or more reactors, and a separation unit, either in the form of flotation or sedimentation, as well as a number of sensors and a control system with a unique and proprietary software. It is also usually appropriate to have a buffer tank before the purification unit to be able to smooth out any flow variations.

Evaluate your water

We have a very good understanding of our system and what it can handle. If you provide a specification for the chemical composition of your contaminated water, we can usually provide expected results directly to you.

If you are interested in testing your water first, we can assist with this at cost. Tests can be performed semi-quantitatively in bench scale (~50 l/h) in our lab or quantitatively in demo scale (~1 m³/h) at your site.

Main challenge

Oil/fat and transition metal ions

This combination is very common and includes applications such as professional cleaning (trains, trucks, buses, etc.), surface treatment, metal processing, paint and coating manufacturing, daywater from ports and industrial areas, oil/biofuel production/handling, tanning, and more.

Main challenge

Microorganisms, nutrients, and fat

This combination is common in the food industry, including dairy farms, fish farming, slaughterhouses, feed production, and carcass handling.

Main challenge

Pollutants in saltwater

Sometimes there is a desire to remove everything except salt from a flow of saltwater. This can apply, for example, to fish farming in saltwater, but also to leaching of ashes or purification of an electrolyte. We can selectively remove most pollutants without removing salt from saltwater, something very few other techniques can do.

N.B. AxoPur is not suitable for desalinating seawater for drinking water.

Main challenge

Water containing hazardous waste and toxic substances

This may involve, for example, leachate from a landfill which often consists of a large amount of more or less known pollutants including oil, heavy metal ions, PFAS, microplastics, etc. To safely treat such water, a broad-spectrum process like AxoPur is a very good option. Depending on how long the treatment needs to be operated, a second polishing step may also be recommended here.